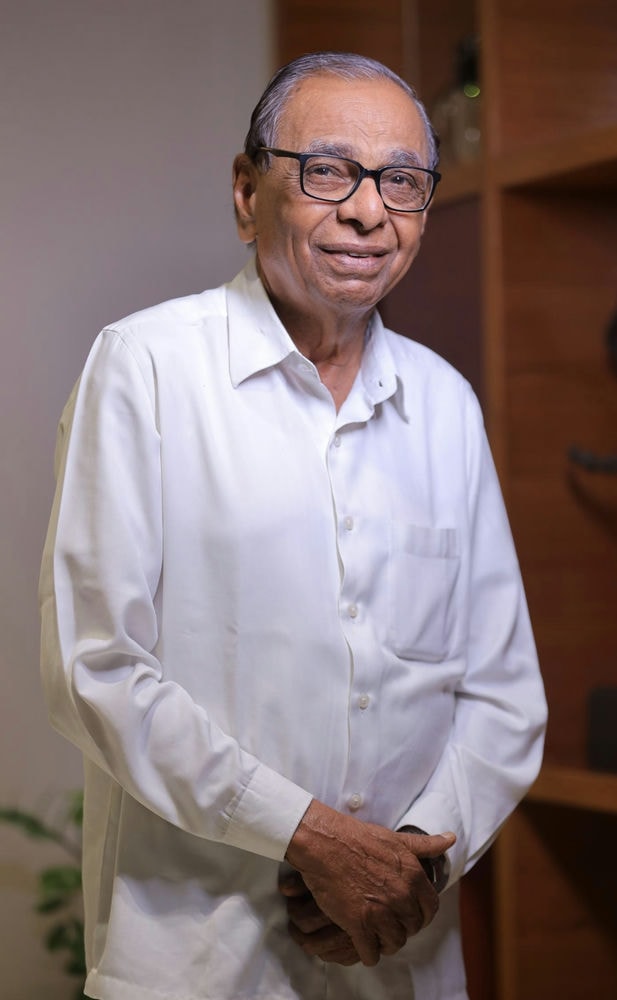

2017 is a milestone for the company as Colourtex completes fifty years in the service of textile and leather industry.

2017 is a milestone for the company as Colourtex completes fifty years in the service of textile and leather industry.

I derive great satisfaction of having steered the organization to its position of leadership in the domestic dyestuff industry. Today Colourtex products are industry bench mark for quality and performance.

All my thoughts and actions in past five decades have focused on enhancing life of the organization through prudent backward integration, capacity expansion, building comprehensive manufacturing infrastructure, pragmatic product pricing and being customer centric.

I have always viewed dyestuff business as responsibility and all my efforts have been to build trust and win confidence of customers.

Credit for achieving phenomenal growth and creating company goodwill goes to my people.

Ecological commitments in dyestuff manufacture and use are paramount to Colourtex and we shall ensure their compliance at every step of manufacturing activity.

I cherish a vision to transform Colourtex in to “a global market leader in textile and leather dyes”.

Jayantibhai Jariwala,

Founder, Chairman & Managing Director

Overview

Founded in 1967 by the present Chairman and Managing Director Mr. Jayantibhai Jariwala, Colourtex commenced dyestuff manufacturing in 1976 at Pandesara, an industrial suburb of Surat, Gujarat.

Today, Colourtex manufacturing capabilities are unmatched in Indian subcontinent.

Colourtex owes its strength to its sound infrastructure with surface water reservoir, co-generation coal based turbine, dedicated land fill site and strong backward integration built over four decades.

With a strong marketing and distribution network backed by competent technical services located in all textile & leather centers around the country, Colourtex reaches out to more than two thousand potential customers to provide solutions for coloration of textiles and leather.

An uncompromising attitude of the Chairman & Board of Directors toward environmental and ecological priorities augurs well for future of Colourtex.

Colourtex is ETAD member since 2006 and ‘bluesign’ system partner.

In 2017 Indian Chemical Council (ICC) – representative of International Council of Chemical Association (ICCA) conferred on Colourtex “Responsible Care” certification acknowledging its achievement in establishing systems for environmental and safety compliance in dyestuff manufacturing and use across the supply chain.

To know more, click to download the Colourtex Corporate Brochure:

CORPORATE BROCHURE

Our Vision to be a global market leader in the textile & leather industry

Our Vision

To be the global market leader in Textile and Leather Dyes.

Our Mission

To achieve sustainable growth

and total customer confidence with utmost care

of Environment and Ecology.

Corporate Social Responsibility

Being a Responsible Care company, CSR is a key business process at Colourtex.

Colourtex shall act as a good corporate citizen in performing its duty for welfare of the society, within the framework of CSR policy.

The Corporate Social Responsibility Policy of Colourtex has been approved by the Company’s Board of Directors at its meeting held on 01st May, 2014.

In line with the provisions of Section 135 of the Companies Act, 2013, Colourtex envisages to spend each year minimum two percent of the average net profits made by Company during the three immediately preceding financial years of the Company.

Colourtex's Corporate Social Responsibility Committee comprises of:

- Shri. Jayantilal T. Jariwala, Chairman

- Shri. Vishadkumar J. Jariwala, Member

- Shri. Pravinchandra D. Kabutarwala, Member

- Shri. Kanakkumar J. Jariwala, Member

- Shri. Maheshchandra D. Kabutarwala, Member

Colourtex shall seek to identify suitable programs / projects / activities as enumerated under Schedule VII of Companies Act, 2013, during the each year to ensure its contribution to the community and society at large.

Vigil Mechanism

This may be called the Vigil Mechanism and Whistle Blower Policy ('the Policy') framed pursuant to section 177(9) of the Companies Act, 2013.

Applicability:

2.1 This Policy applies to all Employees/Directors, regardless of their location. Violations will result in appropriate disciplinary action.

Policy

3.1 Responsibility to Report

Disclosures are to be made whenever an employee becomes aware of actual or suspected;

a. fraudulent practices, such as improperly tampering with the books and records, or theft of company property;

b. corruption, including bribery and money laundering;

c. breaches of the Code of Conduct.

The Disclosure should be made promptly upon the Employee becoming aware of the above matter.

The role of a Whistle-blower is limited to making a disclosure. A Whistle blower should not engage in investigations concerning any of the above matters that is the subject of a disclosure. Neither should a Whistle-blower become involved in determining the appropriate corrective action that might follow from the submission of such disclosure.

3.2 Reporting Mechanism

3.2.1 Colourtex Industries Private Limited (CIPL) has established an Ethics & Vigilance Committee to process and investigate such disclosures. The Ethics & Vigilance Committee operates under the supervision of Director Shri. Vishadkumar J. Jariwala. Disclosures are to be made to the

Committee in the prescribed format as follows:

Capabilities

Dedicated Team of well qualified, skilled and experienced work force at Colourtex possess high degree of expertise in conducting most unit processes and operations involved in the manufacturing of dyestuffs and intermediates.

+ Acetylation

+ Alkaline Fusion

+ Alkylation

+ Ammonolysis

+ Cholosulphonation

+ Condensation

+ Cyanation

+ Cyanoethylation

+ Diazotization & Coupling

+ Esterification

+ Ethoxylation

+ Fractional Distillation

+ Halogenation

+ Nitration

+ Saponification

+ Sulphonation

With state-of-art manufacturing facilities and dedicated infrastructure, Colourtex has emerged as the most reliable Dyestuff company.

Quality

At Colourtex, quality comes first and is the last word.

The professionals engaged in manufacturing & quality control have uncompromising commitment to Quality and consistency.

Highly advanced instrumentation together with well-qualified and experienced work force has lent credibility to Colourtex through consistent quality of its products.

The quality control function examines incoming raw materials, conduct analytical in-process checks and inspect the finished products for compliance to specifications thus ensuring that the products reaching the customers meet the specified requirements.

An independent Quality assurance set up monitors Quality through random sampling of finished & packed materials.

Instrumentation for Quality Control

+ UV-Vis-IR spectrophotometers

+ Data Color SF 600

+ Gas Chromatograph

+ GCMS

+ HPLC

+ Laser Diffraction Particle Size Analyzer

+ Potentiometric Titrator

+ Photo-Fluorimeter

+ Ion chromatography

+ Ion coupled plasma spectrometer

+ HPTLC

+ LCMSMS

+ Differential scanning Calorimeter

RESPONSIBLE CARE POLICY

Environmental, Quality, Occupational Health and Safety

ISO 9001 : 2015

Quality Management

System